Description

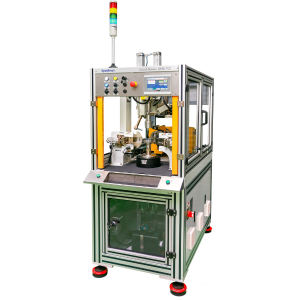

The square and rectangular conductors used in Inverter Transformers are wound using a

Segment Winding Machine. Similarly, the machine may be put to work winding the

segmented poles that are integral to the electrical systems of electric three-wheelers.

Specifications:

- Strong body that can effortlessly deal with both single and double conductors, as

well as a high-torque geared AC motor. - Compact winding is made easier by pressing rollers that are activated by compressed

air. - Uniform tension of conductors throughout the winding cycle is achieved using

pneumatic calliper brake tensioning of the de-reeler type. - Facilitates effortless anchoring of the conductor with a tension release function to

reduce operator fatigue.

| Number of Spindles | 1 |

| No. of Conductors | 1 (as standard); 2 (optional) |

| Wire Size | Strip: Conductor Width: 3mm to 6mm Conductor Thickness: Upto 3mm |

| Round: Ø1mm to 5mm | |

| Coil Swing Diameter | Ø250mm |

| Traverse Length | 250mm |

| Traverse Drive | AC servo motor |

| Winding Speed | 60 RPM @ max. torque; 90RPM @ max. speed |

| Spindle Drive | Geared AC servo motor |

| Spindle Torque | 100Nm |

| Pressing Roller | Pneumatically actuated |

| Pressing Force | 50kgf |

| Controller | PLC based - Delta or Equivalent |

| Motors & Drives | Delta or Equivalent |

| Operating Panel | 5.7" Touchscreen |

| Pneumatics | SMC, Festo or Equivalent |

| Machine Size | 750 x 670 x 1480 mm (L x W x H) |

| Machine Weight | 250 Kg (approx.) |

| Power Supply | 230Vac, 1 Phase |

Reviews

There are no reviews yet.