Pages

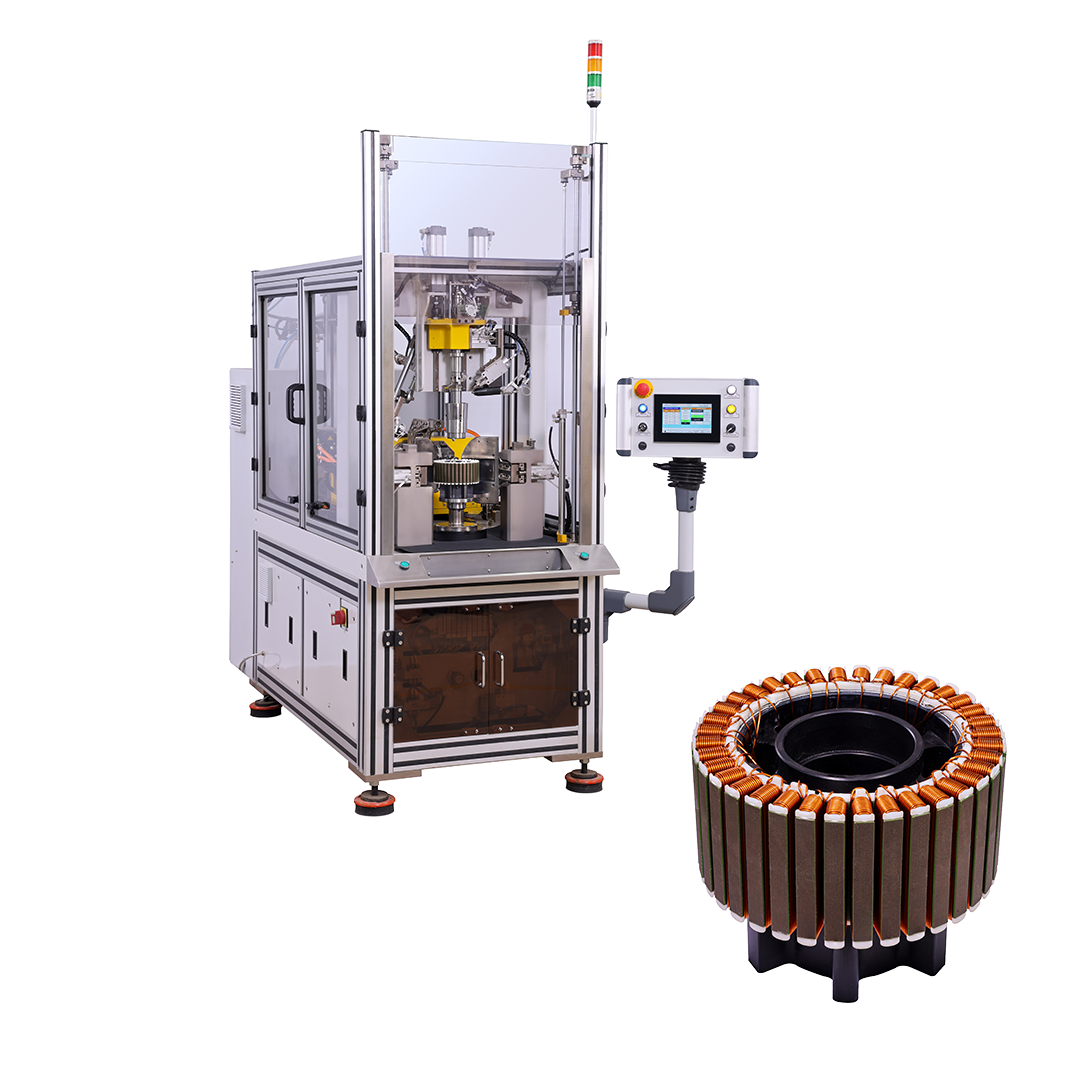

- SWM 100s

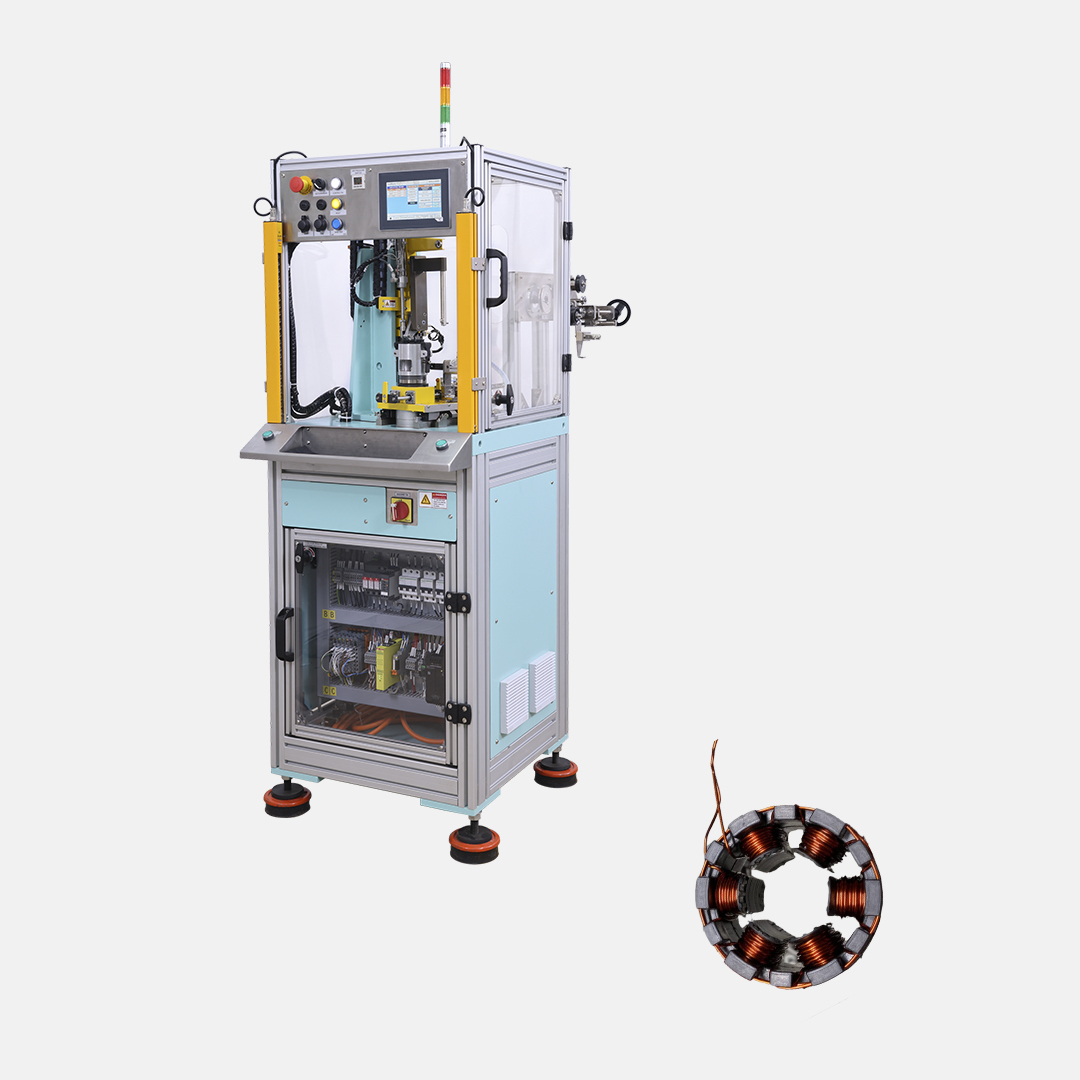

- SSWM

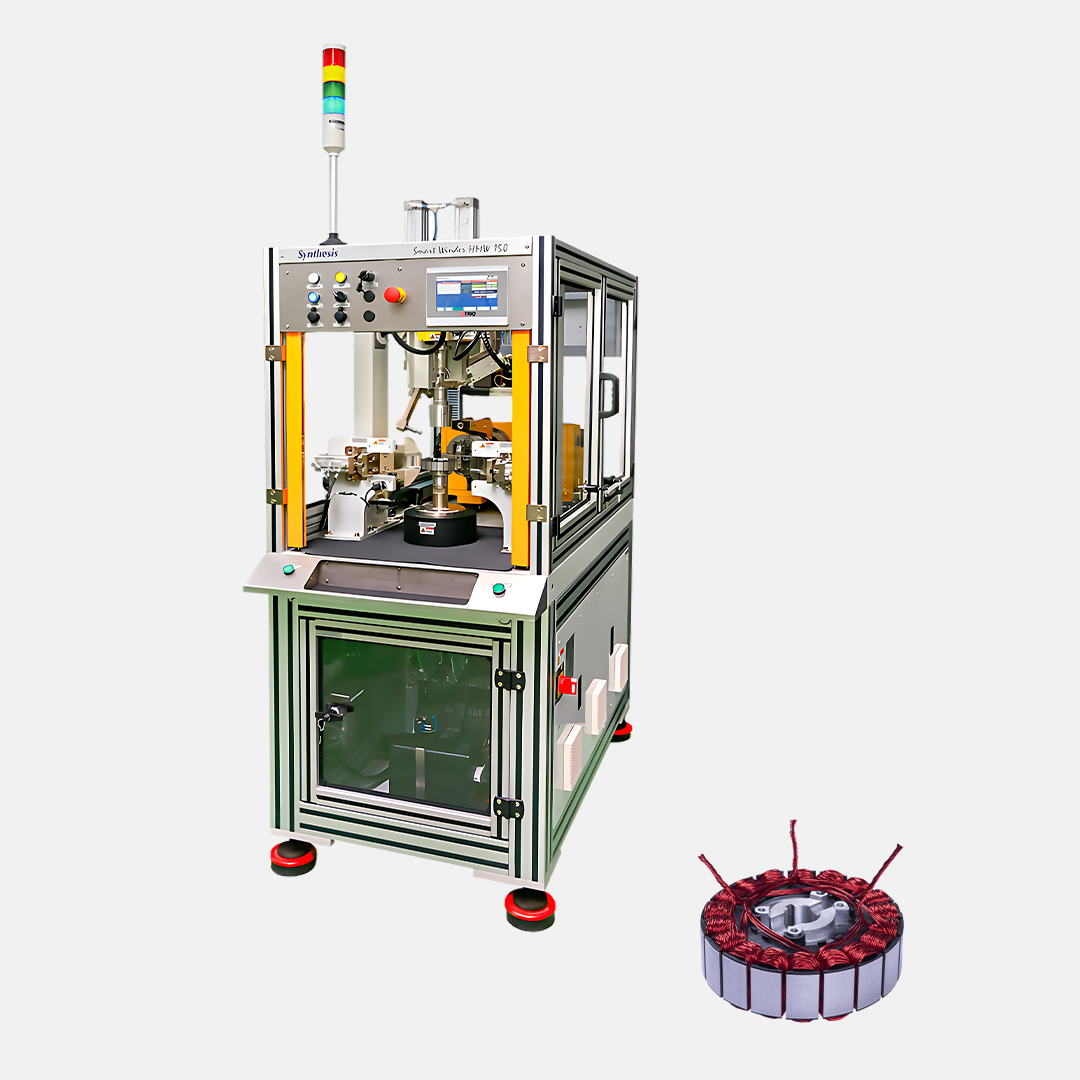

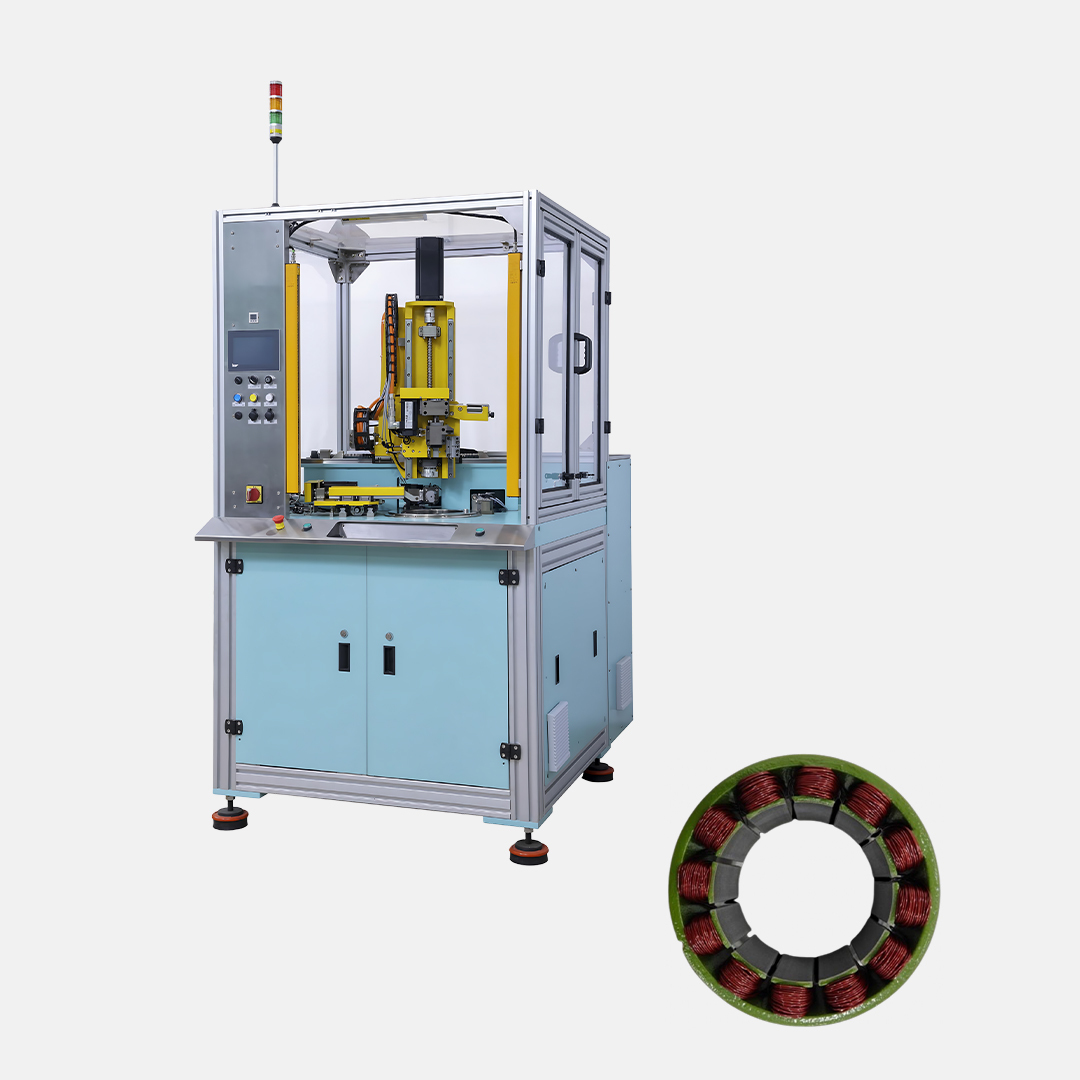

- IST 1-200

- IST 1-120

- IST 1-120

- DMW-1 and DMW-4

- ST1-200

- Careers

- Winding Lab

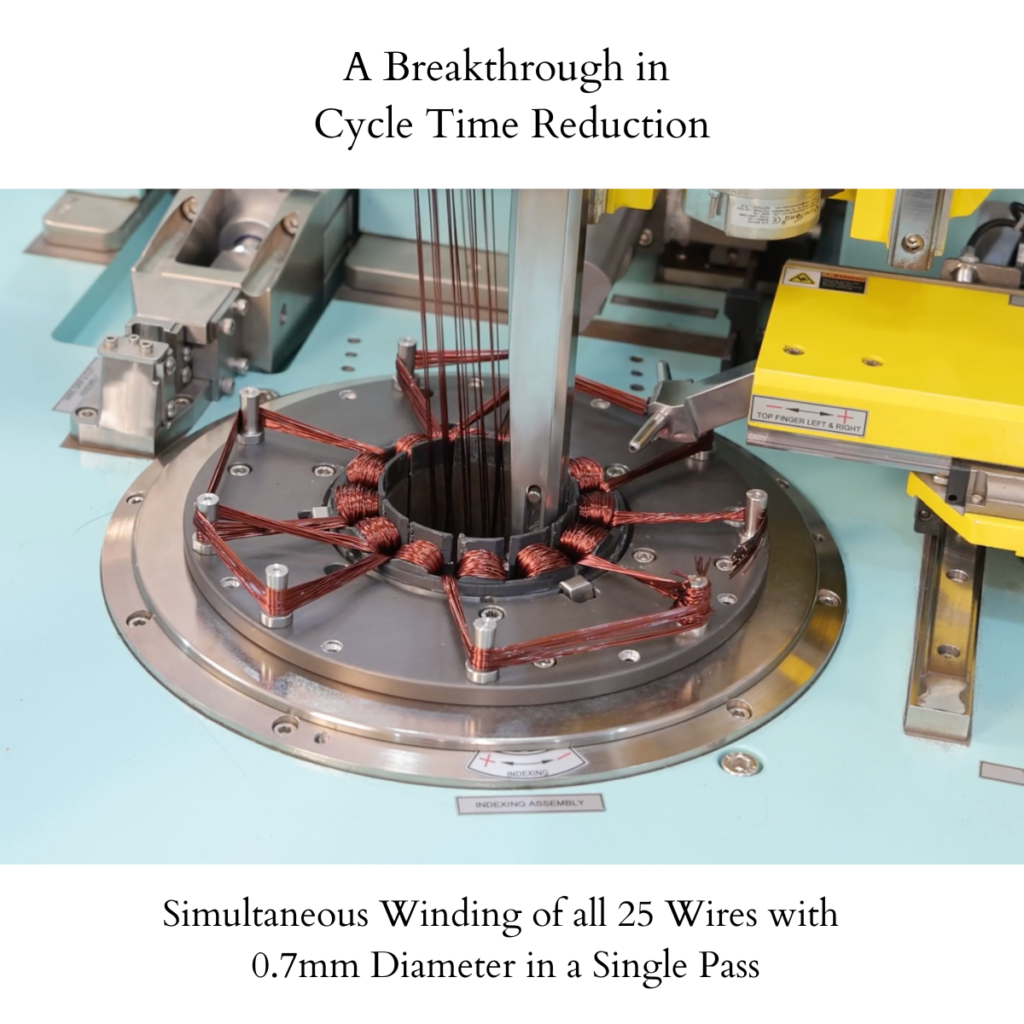

- Breakthrough in Cycle time reduction with MMW160

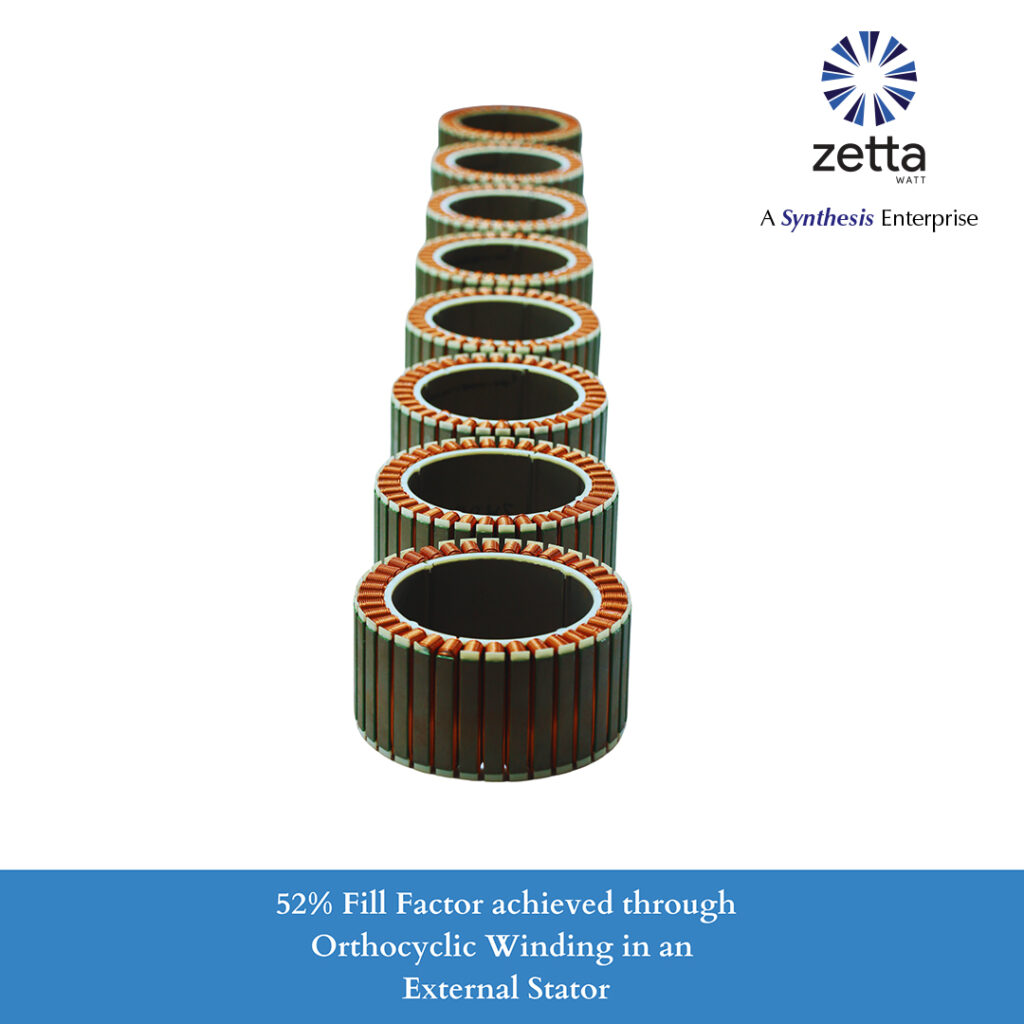

- Achieving Optimal Fill Factor in a Stator Using Orthocyclic Winding

- ST-U

- Home-x

- Home 3

- Test bg cnst

- Home 2

- circle test

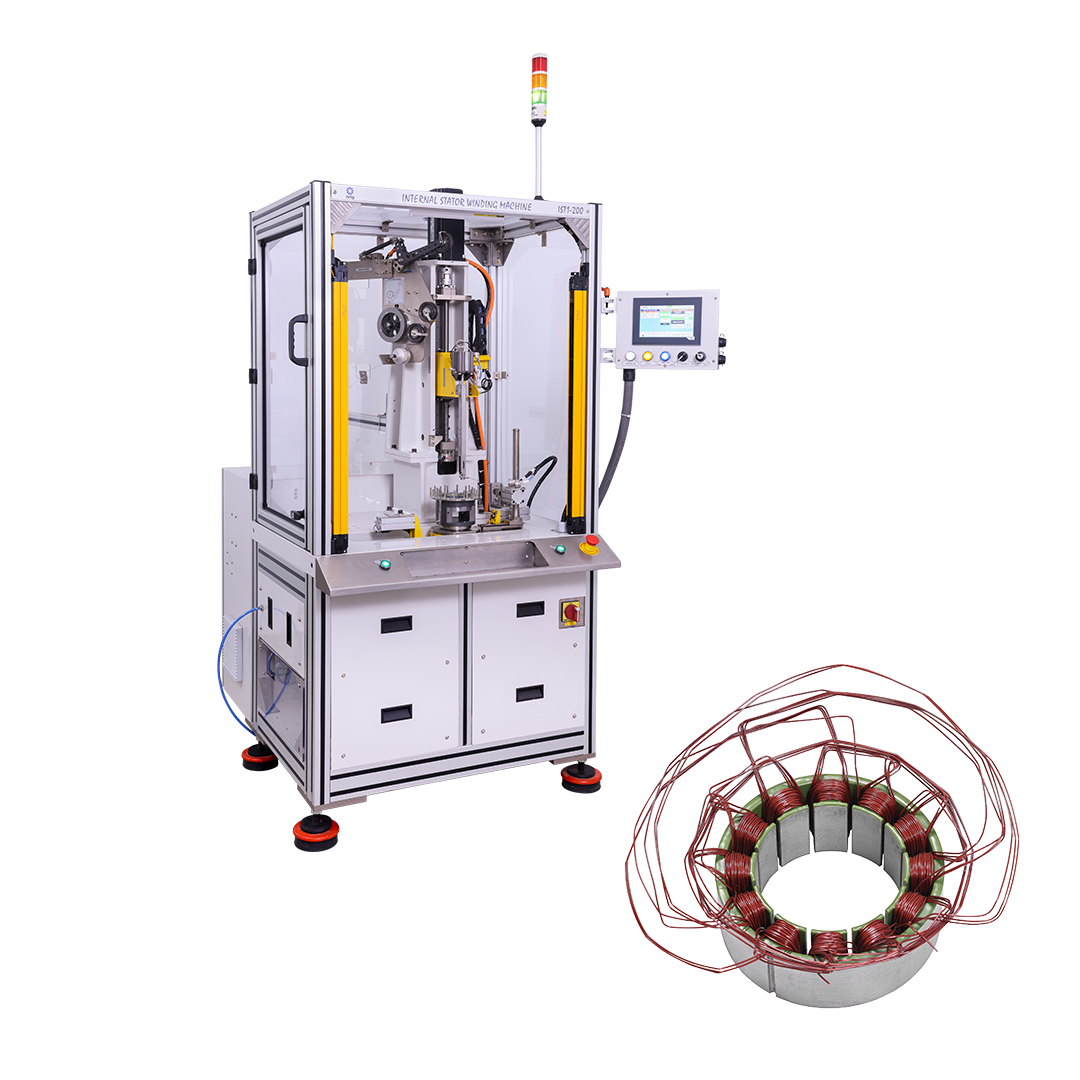

- MMW 160

- IST 2

- SWM 250

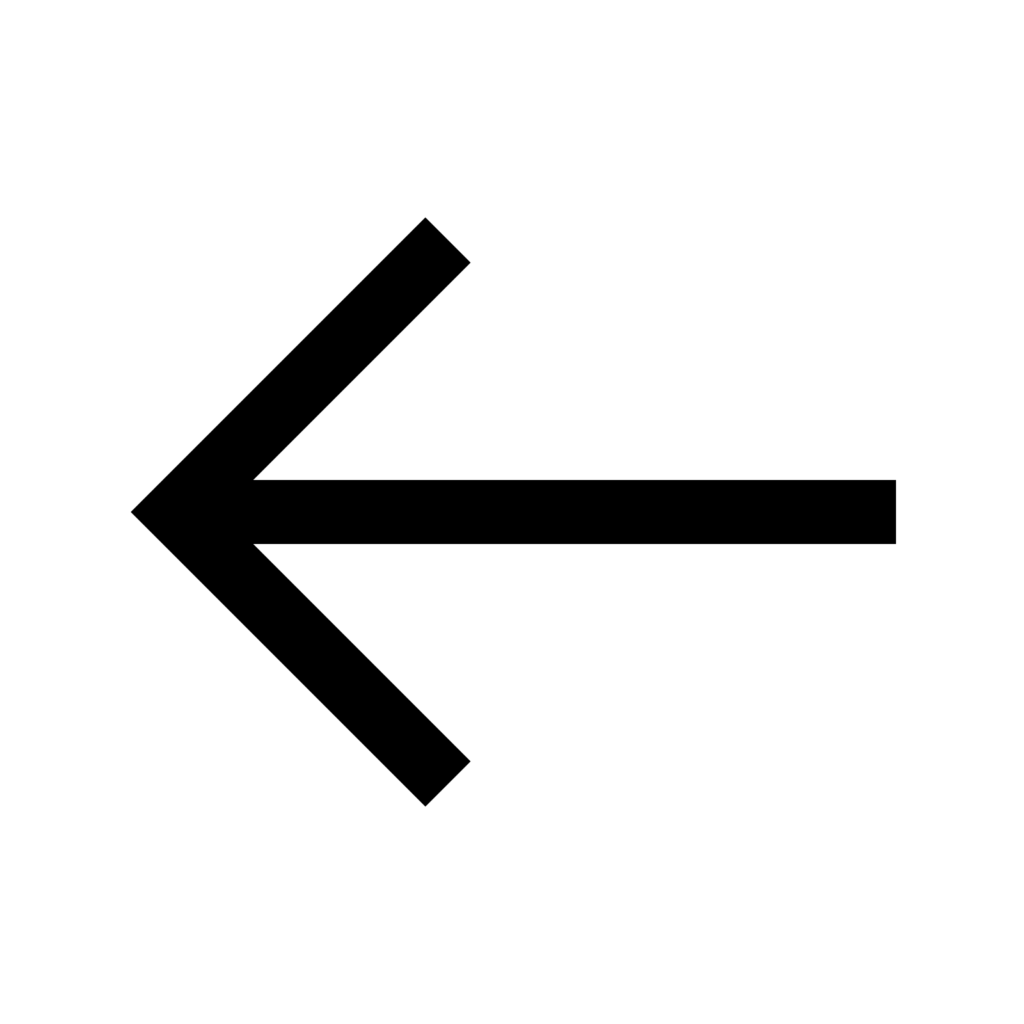

- HMW 150

- HMW 300

- LSW 350

- test

- pro

- Header 2

- Gallery

- Contact Us

- Blog

- Products

- My account

- Checkout

- Cart

- Shop

- About us

- Home

- Sample Page