Building the Backbone of India’s Drone Revolution: Why Indigenous Winding Technology Matters

- Home

- Single Blog

India’s Drone Growth Story

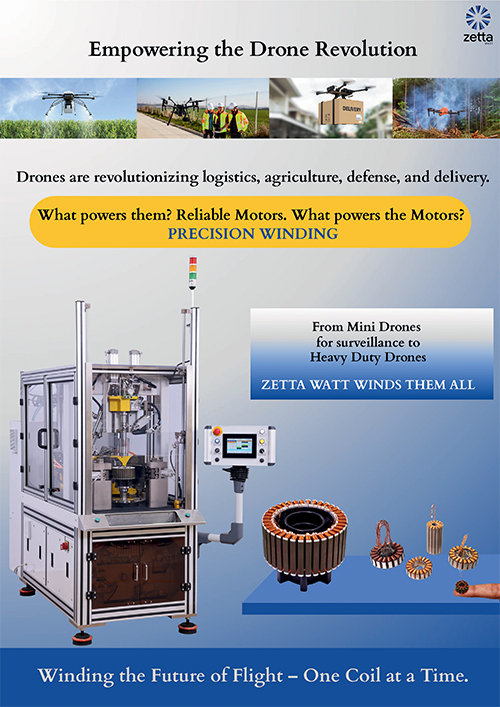

India’s drone industry is soaring. With government initiatives like the Drone Rules 2021, PLI schemes, and drone corridors for logistics and surveillance, the sector is expected to reach $23 billion by 2030. From agriculture and infrastructure mapping to defense and delivery, drones are reshaping how we live and work.

Yet, amid this growth, one critical component remains heavily dependent on imports — high-efficiency drone motors. The backbone of every UAV, these motors determine flight stability, endurance, and payload capacity. For India to truly lead in drone manufacturing,indigenous, high-precision winding solutions are essential.

The Dependence Problem

Even the most innovative drone designs often rely on imported winding and motor assemblies. This dependence creates multiple challenges:

- Higher Costs and Lead Times: Shipping, customs, and vendor delays impact production schedules.

- Inconsistent Quality: Varying winding standards across suppliers affect performance and reliability.

- Limited Customization: Imported motors often come with fixed winding configurations unsuitable for India’s diverse drone use cases (agriculture, logistics, defense).

- Difficult After-Sales Support: Lack of local expertise slows maintenance and upgrades.

To stay competitive, Indian manufacturers must take winding technology into their own hands.

How Portable Winding Bridges the Gap

That’s where Zetta WATT’s Drone Motor Winding Machines (DMW Series) step in — designed specifically to bring motor production in-house, making localized motor manufacturing both practical and precise.

These machines enable drone companies to:

- Produce motors at their own facility — no waiting on imports or third-party suppliers.

- Prototype rapidly — test multiple motor configurations in a single day.

- Reduce dependency — by controlling every step from winding to motor assembly.

- Train locally — with easy-to-learn, intuitive interfaces.

By combining automation, precision, and portability, the DMW series empowers MSMEs and startups to scale faster while staying cost-efficient.

Advantages for Drone Manufacturers

1. Faster Turnaround:

In-house motor production shortens development cycles dramatically. Design, wind, test, and fly — all within days.

2. Cost Savings:

Eliminate high-volume minimum orders from vendors. Manufacture only what you need.

3. Empowered R&D:

Experiment with custom wind counts, wire gauges, and geometries using programmable settings.

4. Sustainability:

Local production reduces shipping emissions and material waste.

Zetta WATT’s Drone Motor Winding Machine Series

Zetta WATT offers two models designed for precision and scale:

DMW-1 (Single Station Machine)

- Ideal for prototype and small-batch production.

- Flyer-type winding head for uniform coil formation.

- Automatic core indexing and servo-actuated finger opening.

- Electronic wire tension control via PLC ensures consistent tension throughout the winding process.

DMW-4 (Four Station Machine)

- Engineered for mass production and parallel operation.

- Automatic wire cut and gripping for uninterrupted cycles.

- Smart-Detect material exhaust sensing minimizes wire wastage.

Multi-axis high-performance controller with multi-program memory and PC interface. - Windows-based GUI for flexible menu-driven programming and complex winding configurations.

These specifications ensure compatibility with the wide range of motors used in drones for agriculture, logistics, and defense applications.

Conclusion: Local Manufacturing = Global Competitiveness

India’s drone revolution is not just about flying higher — it’s about building smarter, faster, and more self-reliant. By adopting portable winding technology, manufacturers can bring motor innovation home, strengthen supply chains, and elevate India’s position in the global UAV market.

Zetta WATT’s DMW series represents the next step in this evolution — compact, intelligent, and proudly made in India.

How to Choose the Right Winding Machine for Your Application

Selecting the right winding machine is crucial for optimising your production processes and ensuring the quality and efficiency of your electric motors. With a plethora of options available, making the right choice can be daunting. At Zetta WATT, we specialise in providing advanced winding machines tailored to meet a wide range of needs. In this blog, we’ll guide you through the key factors to consider when choosing the right winding machine for your application.

1. Understand Your Application Requirements

Assess Motor Specifications:

The first step in choosing a winding machine is to thoroughly understand the specifications of the motors you will be producing. Consider the type of motor (AC, DC, stepper, etc.), the size, the number of windings, and the complexity of the coil design.

Key Questions to Ask:

- What are the physical dimensions and wire gauge requirements?

- How many turns per coil are needed?

- What type of insulation and wire material will be used?

Example Application: For producing high-efficiency AC motors, you might need a machine capable of handling fine wires and precise winding patterns to achieve optimal performance.

2. Determine the Required Production Volume

Assess Production Capacity:

Consider your current and future production needs. Are you producing motors in small batches or at a high volume? Your winding machine should be able to scale with your production requirements without sacrificing quality or efficiency.

Key Questions to Ask:

- What is the expected output per day or per shift?

- How much flexibility is needed for varying production volumes?

- Do you anticipate an increase in production demand?

Example Application: For high-volume production lines, automated winding machines with quick changeover capabilities are ideal to minimise downtime and maximise throughput.

3. Evaluate Automation and Precision Needs

Automation Level:

Decide on the level of automation that suits your production process. Fully automated machines are ideal for high precision and large-scale production, while semi-automated or manual machines may be sufficient for smaller, specialized runs.

Key Questions to Ask:

- How important is precision in your winding process?

- Are you looking for a fully automated solution or a more hands-on approach?

- What are the costs and benefits of automation for your operation?

Example Application: In the aerospace industry, where precision is critical, fully automated machines with advanced controls and sensors ensure consistent, high-quality windings.

4. Consider Flexibility and Customization

Flexibility:

Your winding machine should be flexible enough to handle different types of windings and configurations. This is especially important if you produce a variety of motor types or frequently change designs.

Key Questions to Ask:

- Can the machine accommodate various coil shapes and sizes?

- How easy is it to reconfigure the machine for different winding patterns?

- Does the machine support modular tooling and fixtures?

Example Application: For manufacturers producing custom motors for diverse applications, a machine with modular capabilities allows for easy adaptation to different coil specifications.

5. Analyse Cost and ROI

Cost Considerations:

While it’s essential to stay within budget, it’s equally important to consider the long-term value and return on investment (ROI) that the winding machine will provide. Higher initial costs may be justified by increased efficiency, reduced labor costs, and lower scrap rates.

Key Questions to Ask:

- What is the total cost of ownership, including maintenance and operational costs?

- How quickly will the machine pay for itself through increased efficiency or reduced defects?

- Are there financing or leasing options available to spread the cost?

Example Application: For small businesses or startups, investing in a cost-effective yet capable machine can provide the necessary balance between budget constraints and production needs.

6. Assess Support and Service

After-Sales Support:

Reliable after-sales support and service are critical when investing in a winding machine. Ensure that the manufacturer provides comprehensive training, technical support, and readily available spare parts.

Key Questions to Ask:

- What kind of training and support is included with the purchase?

- How quickly can technical support respond to issues?

- Are spare parts readily available, and what is the lead time for replacements?

Example Application: For companies with in-house maintenance teams, access to detailed manuals and quick-response technical support is vital to minimise downtime.

7. Check for Compliance and Standards

Compliance:

Ensure that the winding machine complies with industry standards and regulations relevant to your operations. This includes safety certifications, quality standards, and environmental regulations.

Key Questions to Ask:

- Does the machine meet all relevant safety and quality standards?

- Are there any specific certifications required for your industry?

- How does the machine support your compliance with environmental regulations?

Example Application: In the medical device industry, winding machines must comply with stringent quality standards and safety regulations to ensure the reliability and safety of the end products.

Conclusion

Choosing the right winding machine is a critical decision that can significantly impact your production efficiency, product quality, and overall operational success. By carefully considering your specific application requirements, production needs, automation level, flexibility, cost, support, and compliance, you can make an informed decision that aligns with your business goals.

At Zetta WATT, we offer a wide range of winding machines designed to meet the diverse needs of our customers. Our team of experts is here to help you find the perfect solution for your application.

Interested in finding the right winding machine for your needs? Contact us today to learn more about our products and how we can tailor our solutions to meet your specific requirements.